Screen film radiography is the use of silicon films within a cassette being placed behind the object to be imaged and exposed to an x-ray...

Screen film radiography is the use of silicon films within a cassette being placed behind the object to be imaged and exposed to an x-ray beam. These films are then processed. In the UK this method of imaging is no longer performed, including for mammography (as far as we are aware!).

Film

Types of screens

- Double-sided radiographic film: emulsion layer of light-sensitive crystals coated onto both sides of a transparent base material. Used most in plain film imaging

- Single-sided camera film: one emulsion layer only. Used in mammography

- Non-screen film: x-ray photons used directly to expose film. Used in dental x-rays

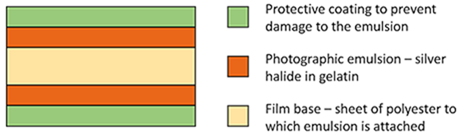

Basic structure

Base

- Clear polyester material about 150 μm thick

- Provides physical support of the other film components

- Does not participate in the image-forming process

Emulsion

- Active component in which image is formed

- Typically 5 - 10 μm thick

- Consists of many small, irregularly-shaped silver halide crystals suspended in gelatine

- The silver halide used is typically silver iodobromide (90-99% bromide, 1-10% silver iodide)

- Each grain has a structural "defect" built in called the "sensitive spot". Each crystal is 1 μm large

- Most sensitive to light energy, not x-ray photons, so intensifying screens used

Forming an image

An image is formed on film by:

- Exposure to radiation

- Development of film

- Fixing

1. Exposure to radiation

- Unexposed film: each silver bromide grain contains a number of free Ag+ and Br- ions. The sensitive spot is caused by a crystal structural imperfection.

- Exposure: absorption of light photons by the bromide ions frees the extra electrons which move to and get trapped by the sensitive spot. This causes it to become negatively charged. A positive silver ion is attracted to the spot and neutralised, depositing an atom of black silver.

- Repeated exposure: process repeated as more photons reach the grain to cause several silver atoms to be deposited. This forms the latent image. 10-80 photons are needed to make to grain developable.

2. Development of film

The latent image is invisible. It is converted into a visible image through the process of chemical development. The developer supplies electrons that migrate into the exposed grains in the silver bromide and converts the other silver ions into black metallic silver:

AgBr + electron = Ag + Br

Only exposed grains accept these electrons as their negatively charged bromide layer has been breached through exposure. Given enough time, the developer will also penetrate the unexposed crystals producing background fog.

Develop solutions contain:

- Reducer: supplies electrons e.g. phenidone

- Activator: soften and swell the emulsion so that reducers can reach exposed grains. Usually sodium carbonate

- Restrainer: moderates rate of development. Usually alkali such as potassium bromide

- Preservative: protects reducing agents from oxidation because of their contact with air. Reacts with oxidation products which accumulate to reduce their activity which would otherwise retard development and stain the film. Usually sodium sulphite

3. Fixing

The film is immersed in fixer solution so that the unexposed and unreduced silver halide is removed to render the image stable in white light. The fixer solution contains:

- Neutraliser: acetic acid to stop ongoing development after removal from developer solution

- Clearer: ammonium or sodium thiosulphate used to clear the undeveloped silver halide grains from the film

- Preserver: sodium sulphite

- Hardener: aluminium chloride shrinks and hardens the emulsion to produce final film

Automatic processors

An automatic processor:

- Unloads the film from the cassette

- Transports the film through the processing chemicals in the right order

- Produces a developed, hardened and dried film

Now available to download!

Written by radiologists, for radiologists with plenty of diagrams to explain complicated concepts in an easy-to-follow way. An excellent resource for radiology physics revision.

Written by radiologists, for radiologists with plenty of diagrams to explain complicated concepts in an easy-to-follow way. An excellent resource for radiology physics revision.

Optical density

The darkness of the film increases as the exposure is increased. This is measured as the optical density, which is a log scale of the blackness of the film

D = log10 (I0 / In)

where:

D = optical density

I0 = intensity of incident light beam

In = intensity of transmitted light beam at n

D = optical density

I0 = intensity of incident light beam

In = intensity of transmitted light beam at n

Double sided film increases the optical density for the same exposure (the total optical density equals the sum of optical densities produced by each film).

| Optical density | Film |

| 0 | Clear piece of film that allow 100% of light to penetrate. The minimum density is usually in the range of 0.15 to 0.2 density units because radiographic film is never completely clear. The value is designated as base plus fog density |

| 1 | Each unit of density decreases light penetration by a factor of 10. A film area with a density value of 1 allows 10% of light to penetrate |

| 2 | This allows 1% (10% of 10%) of light penetration. It is possible to see through areas of film with density values up to ~2 units |

| 3 | This allows 0.1% of light to penetrate |

The characteristic curve

The behaviour of the film when exposed to light is represented by its characteristic curve.

- Low exposure (Toe): small increases in exposure produces hardly any change in density resulting in a white image with no contrast

- Base plus fog: density produced on unexposed part of a developed film due to the density of the film itself and blackening caused by the emulsion. It is usually in the range of 0.15 to 0.2. This increases if the film is stored for a long time or at too high a temperature.

- Linear region: at high exposures the probability of producing a developable crystal increases with exposure. This is the region of most use and provides the highest contrast

- High exposures (shoulder): at high exposures nearly all crystals will be developed resulting in a dark image with no contrast

- Dmax: maximum density that a film can reach when all the grains are developed. Usually 3.5 to 4. Depends on the characteristics of the film and processing conditions.

Film speed

Aka the sensitivity. This determines the amount of exposure needed to produce an image. The sensitivities of films are generally compared by the amount of exposure required to produce an optical density of 1 unit above the base plus fog density.

speed = 1000 / (air kerma required for density of base-plus-fog + 1)

The typical speed for a rare earth film screen combination is 400

- High sensitivity: requires less exposure but produces more noise

- Low sensitivity: used to reduce image noise

Contrast

- Radiation contrast: aka subject contrast. The ratio of radiation intensities that reach the film through the different tissues or structures (a property of the object being imaged). It is affected by the radiation wavelength, the intensity and distribution of scatter and the absorption differences of in the subject being imaged.

- Radiographic contrast: The difference (not ratio) between optical densities produced in areas of the film. This is dependent on the type of film used, how much exposure it encountered, and how it was processed.

Latitude

- Types of latitude:

- Film latitude = range of exposures that will result in a density in the useful range of optical densities (usually 0.25 to 2)

- Exposure latitude = range of relative exposure that will produce a radiograph with optical densities within the useful range

- Altering exposure latitude:

- Wide latitude = greater range of soft tissues visualised but poor contrast

- Narrow latitude = smaller range of soft tissues visualised but higher contrast

Gamma

The gamma is the ratio between radiographic contrast and radiation contrast, i.e. the slope.

- High gamma: steep slope, high contrast

- Low gamma: shallow slope, low contrast

Effect of grain size

- Large grain size: fast emulsion. A larger grain presents a larger target for photons so fewer photons are needed to blacken film resulting in a faster film

- Variable grain size: small gamma. Grains of a uniform size tend to become developable at the same exposure. Therefore, that the range of exposures going from low to high density is small resulting in a large gamma.

Intensifying screen

With emulsion, it has to be thick enough to absorb enough photons to produce a decent image. However, a thicker screen increases the scatter as photons will have more material to travel through and cause scatter. An intensifying screen is placed in front of the film to amplify the photons and increase the signal to the film without needing a thicker emulsion.

Intensification factor = exposure required to produce given optical density without screen

exposure needed with screen

exposure needed with screen

Advantages

- A screen can absorb 20-40 times more x-rays than film alone

- A single x-ray photon can cause the emission of about 1500 light photons

- The same optical density can be achieved with smaller exposures (reduction factor 30-300) than when film used alone

- Increased gamma

Properties

The intensification screen needs a large attenuation factor to absorb the largest number of photons instead of allowing them to have enough energy to pass straight through. This is achieved by it having:

- High density

- High atomic number (Z)

- A favourable k-edge

Material

Calcium tungstate was widely used for its atomic number. More recently "rare earth screens" have become the standard. They use gadolinium and lanthanum. Although Tungsten has a higher atomic number (Z=74) than lanthanum (Z=56) or gadolinium (Z=64) the K-edge of lanthanum is at 39 keV and this sudden increase in attenuation takes its mass attenuation coefficient (μ/ρ) above that of tungsten.

Conversion efficiency

Measures the proportion of the x-ray energy that is converted into light. Rare earth screens have a greater conversion efficiency than calcium tungsten. However, a higher conversion efficiency leads to worse resolution.

Colour matching

Different types of screen can produce different colours of light.

- Calcium tungsten produces bluish light

- Rare earth screens produce green light

Because of this the film needs to be used with a specific intensification screen.

Screen thickness

A thicker screen leads to better absorption of x-rays and, therefore, more production of light. However, the thicker the screen the more the spread of light before it reaches the film and, therefore, the greater the screen unsharpness.

- Double sided film: the disadvantages of a thicker screen can be overcome by sandwiching a double-sided film between two screens to add the optical densities of the two emulsions together

- Double screens: reduces the film screen unsharpness but causes other problems:

- Parallax: viewed from A the two images line up. Viewed from B they won't.

- Crossover: when light produced in one screen is transmitted through the film base to produce an image in the opposite emulsion. The increased spread of light means greater unsharpness.

Reciprocity

A greater quantity of radiation from the x-ray tube is produced by:

- Increasing x-ray tube current (mA)

- Increasing exposure time (s)

To give the same mAs you can have a large tube current or a long exposure time = reciprocity.

Usually, the exposure determines the optical density of the image and the combination of current and time used to achieve it does not matter. But, at very small exposure rates (small mA, long s) the level of light in the film may be insufficient to produce a latent image. Image formation has time to reverse before it is complete. This reduction in optical density is called the reciprocity failure.

Anti-scatter grids

Properties

Grid ratio

This is the ratio of the thickness of the grid to the distance between the lead strips. The larger the grid ratio the smaller the angle of acceptance (θ) and the smaller the proportion of scatter that can pass through the grid.

Grid factor

This indicates the increase in exposure and, therefore, the increase in patient dose required to keep the dose to the image receptor the same as without a grid. This is determined by the design of the grid and the amount of scatter present in the x-ray beam.

Primary transmission

This is a measure of how much of the primary (as opposed to the scattered secondary) beam is stopped.

Types of grid

Grids are placed between the patient and the film-screen combination. The most commonly used grids are focused crossed grids. If a focused grid is placed the wrong way around it produces a linear artefact on the film with bands of very low exposure due to the orientation of the grid obstructing the photon beam.

To avoid grid lines the grid is vibrated back and forth so that the lines are blurred out by the motion e.g. the Potter-Bucky grid.

Disadvantages and alternatives

Disadvantages

- Increased dose to patient

- Incorrect usage: when there is less tissue (e.g. paediatrics) the small kV used means the amount of scatter is small enough that the increased dose required by using a grid is not justified.

Alternatives

Instead of using an anti-scatter grid if dose increase is of concern one can use an air gap between the patient and the receptor. Increasing the distance between the patient and the film means scattered photons are more likely to miss the film due to their divergent paths and lower intensities.

Σ Summary

Forming an image

- Exposure to radiation: silver bromide crystals form emulsion. Photons interact with crystals depositing silver ions in proportion to exposure

- Development of film: invisible latent image converted into visible image by chemical development

- Fixing: image rendered stable in white light

Optical density

- Darkness of film measured as a log scale

- Base plus fog density = minimum density due to background fog. Usually 0.15 to 0.2

- Dmax = maximum density film can reach when all grains are developed. Usually 3.5 to 4

Characteristic curve

- Specific to each film-screen combination

- Film speed = sensitivity

- Speed = 1000 / (air kerma required for density base-plus-fog + 1)

- Gamma = steepness of curve

- High gamma = steeper line, smaller latitude and greater contrast

- Low gamma = more shallow line, larger latitude and smaller contrast

- Latitude

- Film latitude = range of exposures that will result in a density in the useful range of optical densities (usually 0.25 to 2)

- Exposure latitude = range of relative exposure that will produce a radiograph with the optical densities within the useful range

- Wide exposure latitude = greater range of soft tissues visualised but poor contrast as low gamma

- Narrow exposure latitude = smaller range of soft tissues visualised but higher contrast as higher gamma

Grains

- Large grain = fast emulsion

- Variable grain sizes in emulsion = small gamma

Intensifying screen

- Rare earth screens (lanthanum and gadolinium) have k-edge that give high absorption

- They also give higher conversion energy

- Artefacts of double screen

- Parallax

- Crossover

Anti-scatter grids

- Grid ratio = thickness / distance between lead lines

- Grid factor = exposure necessary with a grid / exposure without a grid

- Grids are: crossed vs linear. Parallel vs focused

- Advantages

- Reduce scatter

- Disadvantages

- Increased dose

- Incorrect usage (e.g. paediatrics)

- Air gaps can be used instead if dose of concern